Believe it or not, the title doesn’t refer to tulips. Shocking, I know. This is supposed to be a string blog, more or less, and once in a while I get the urge to actually write about string. Honestly, I get the urge a lot, but the followthrough has been somewhat lacking – I have an embarrassingly large collection of half-finished and promised instructional and interesting articles. Today you get a new one on dyeing tips.

The dyes I use on wool and silk – acid dyes and Lanaset dyes – require acid and heat to fix the dye to the fiber. There are many different ways to apply those two factors, depending on the desired effect. Multicolored sock yarn requires different techniques from perfectly even skeins of silk. I was doing both of those things yesterday, and I took some photos to share with you.

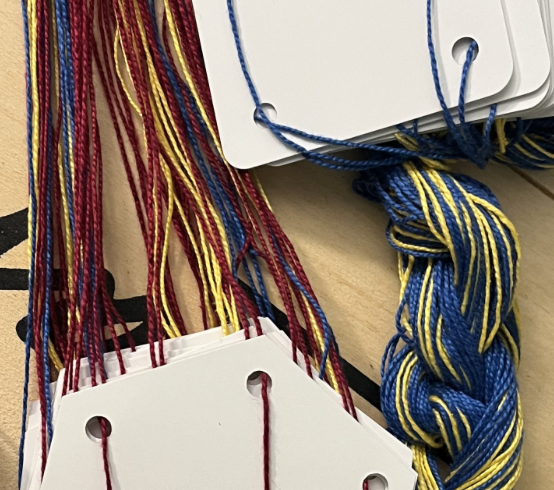

First, the silk. My objective is to get the color as even as possible. I dye the silk on demand so I don’t have to keep a huge inventory on hand. This is interesting – my intent was to put up the silk in small enough lots (100 yards) that tablet weavers could buy four bobbins and do continuous warping. The bobbins are perfect for that. Oddly, nobody does that. Instead, nearly everyone buys a whole bunch of colors instead (and I don’t think everyone who orders from me is weaving Snartemo). This batch is all for one person.

So anyway, I find myself dyeing lots of little skeins in lots of colors at the same time, so I need to heat a lot of separate containers. Getting a smoothly-dyed skein requires a lot of stirring, so I can’t put them in the oven. I don’t have a zillion tiny saucepans, even if they would fit on my stove. My solution: a hot water bath.

Lots of little jars with individual skeins, in a water bath that reaches over the water level in an individual jar. I use a big old stockpot, but a dyeing-only large turkey roaster would be even better, one with a thermostat so I could control the temperature of the hot water bath. (That’s probably going to be the next dye studio investment.)

It works pretty well. Other tips: make sure the yarn is very clean before it goes in the dyebath, and let it spend at least an hour (overnight is good) in water with a bit of Synthrapol or dish soap added. The yarn needs to be thoroughly and evenly wetted before it goes in the dyebath.

Measure carefully. I make up 1% stock solutions rather than weighing dye powder all the time. It makes it easy to measure, and relegates the most hazardous part of the process (where there’s a risk of inhaling fine powders) to an occasional thing rather than a frequent thing. I wear a mask too.

That’s the sciency kind of dyeing. What about the arty kind of dyeing? I still use stock solutions, but I measure much less carefully. The yarn still needs to be clean, but wetting is less important – uneven wetting can be used to create special effects.

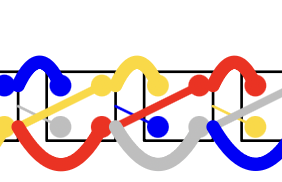

Instead of lots of room to move and plenty of liquid, I use a confined space where yarn and color cannot circulate freely.

This is a disposable oven pan – very useful. There’s just enough vinegar water to wet the yarn. These two skeins were supposed to be blues and grays, not too saturated, so I used 100mL of stock solution for 200g of yarn (0.5% by weight of goods; I use anywhere up to 4% for acid dyes depending on the dye and the desired intensity), half blue and half black, both diluted to double before applying.

First I poured on the blue, then the black, then I played with it for a bit.

The dye won’t automatically penetrate the skein, and will make a darker spot if you pour it directly on the yarn. This can be a feature or not. I wanted to make the yarn a bit more even than that, so I squeezed and stirred with gloved fingers until I had the distribution I wanted. The dye does spread a bit during heating, depending on how much liquid is in the pan.

The pan goes in a 275F oven for about an hour. Let the yarn sit in the pan as it cools since it will continue to absorb some dye. The liquid should be clear by the time the pan is cool.

Here it is, straight out of the oven last night. This morning I rinsed it out: one rinse with synthrapol, followed by 3 rinses in plain warm water, or as many as needed for the last of the unfixed dye to rinse out. With such a low percentage of dye by weight, even the initial rinse came out clear so it didn’t take very long. Intense colors are less-well-behaved, as are reds and yellows, and turquoise.

The skeins turned out to be more gray than blue, not quite what I was aiming for. I don’t do sock yarn as a repeatable process usually, but rather as a series of unique skeins. I don’t keep careful notes on proportions or anything else, unlike for the weaving yarns. These will probably be listed for sale as grays, and I’ll do another pair with more blue and less black.

You didn’t really think you were going to escape without a tulip, did you?

4 responses to “Pretty colors”

I love to see how things are done. I would probably not do well with the careful measuring part as I tend to be a dive in first and ask questions later sort of artist so the arty is probably more for me. It definitely looks like fun though, we’ll have to give it a try.

I picked up a used canning kettle at a garage sale that is perfect for dying. The main advantage over the plain jars-in-kettle method is that it has a metal rack with handles that holds canning jars. It is also a bit taller than a turkey roaster, but made from the same type of enameled metal.

I like your idea of the disposable roasting pan. I have one of those laying around. I’ll have to move it from the spare kitchen stuff to the fiber stuff.

Oh that’s cool – I’ve never seen an enameled canning kettle. I bought this pan

at Goodwill because of the enamel. I’ll have to keep an eye out for an enameled

canning kettle.

The disposable baking pans are very convenient because they’re inexpensive

and actually quite reusable, at least for dyeing. I’ve tried all the common brands,

and the black ones are the sturdiest. Some of the rest tend to flop when full of

hot water, which is dangerous and messy.

Phiala–cool stuff. And now that I’ve had a semester of Chem lab/lecture, I even understand it :)

Seriously, they must do a lot of canning here in New Mexico. The Walmart in Socorro sells a ton of mason jars and, yes, huge enameled canning kettles. I think even the local True Value hardware store sells them seasonally. :)